Modular choice rules.

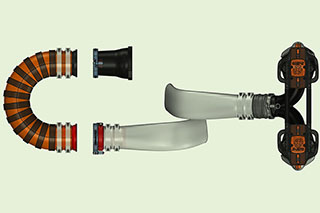

When we initiated the JetBlade project, we looked at the full range of possibilities for the rider – hydro board interface, the bindings. Our lead designer the HydroShaper, spent years designing and manufacturing dozens of models snowboard bindings for virtually all of the leading snowboard brands. Hundreds of thousands of the bindings were used and are in use around the world. He knows that the key to a great product is scale of production, in order to make a great boot or binding, you literally need to build tens of thousands of units. Tooling costs for good molds, batch productions, the best materials, getting it right with quantity. JetBlade riding is nowhere near that scale, manufacturing a specific binding is cost prohibitive. As the sport evolves it is absolutely necessary that the equipment evolve just as fast. The industry standard is wakeboard bindings, they fit the task perfectly and there is a whole industry built to deliver great products around the world. We could have sourced a midrange binding from a middleman, but that would not fit all the requirements of our users.

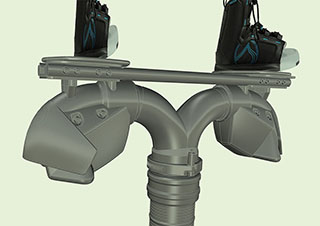

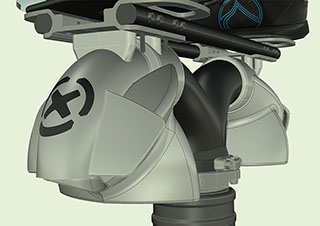

We came to the conclusion that the best option for our customers is to be able to choose a boot and binding from the full range of choices in the market. From fit to style to price range, everything is available online or locally. The full infrastructure of support exists for the widest variety of choice.

We recommend the following bindings from different companies. Liquid Force Vantage, open toe, fits lots of different sizes, velcro straps get you in and out quickly without the extra laces hanging out.

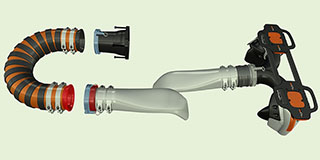

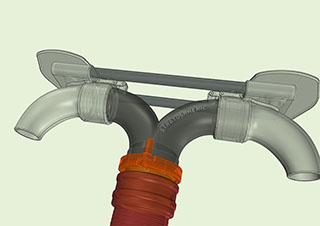

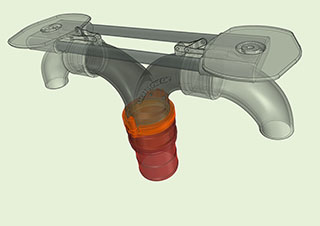

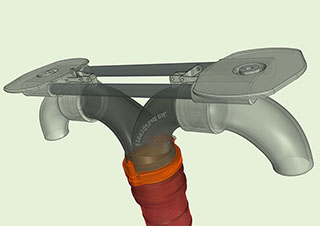

We sell our Sidewinder without a binding, with full compatibility to existing wakeboard boots, bindings and combination systems using a six inch hole pattern.